Why a Solid Roller Camshaft Outperforms a Hydraulic Roller in High-Performance Applications

When building a serious performance engine, one of the critical decisions is choosing between a solid roller camshaft and a hydraulic roller camshaft. Both have their place, but for specific applications—especially where maximum airflow, precision, and reliability are required—the solid roller comes out on top. Here’s why.

Superior Valve Control

With a solid roller camshaft, you gain far greater control over the valve events. Unlike hydraulic lifters that rely on oil pressure to maintain lash, solid rollers operate with fixed lash settings. This allows for much more aggressive cam profiles that would overwhelm a hydraulic lifter’s ability to follow the lobe precisely.

What does this mean in practice?

Even if duration at .050” lift is kept similar to a hydraulic cam, the solid roller profile can dramatically increase the area under the curve—meaning the valve opens faster, stays at high lift longer, and closes more efficiently. This results in significantly more air mass (sometimes up to 30% more) entering the cylinder, which directly translates to more power.

*Side note, generally speaking you can safely run solid roller lifters on your hydraulic roller cam, it will run fine, but it leaves some performance potential on the table compared to a dedicated solid roller lobe profile.

Early Warning of Problems

Solid roller valvetrains provide a clear window into the health of your engine. When you set lash on a solid roller, it stays where you put it—unless something is moving that shouldn’t be. If the lash changes, it’s a red flag that:

-

The cam or lifter may be wearing

-

The valve is stretching (often due to heat or impending failure)

-

Or some other component is shifting

In contrast, hydraulic rollers can mask problems because they automatically adjust lash with oil pressure. A failing lifter or wearing lobe can go unnoticed until it’s too late.

No Hydraulic Lifters to Bleed Down or Pump Up

Hydraulic lifters can introduce variability that you don’t want in a high-performance setup:

-

If they bleed down, you lose lift and duration—your engine isn’t making the power it should.

-

If they pump up (often at high RPM), they can hold a valve open when it’s supposed to be closed, leading to loss of compression and possible engine damage.

Solid rollers eliminate these risks entirely. You have a direct, mechanical connection with no guesswork.

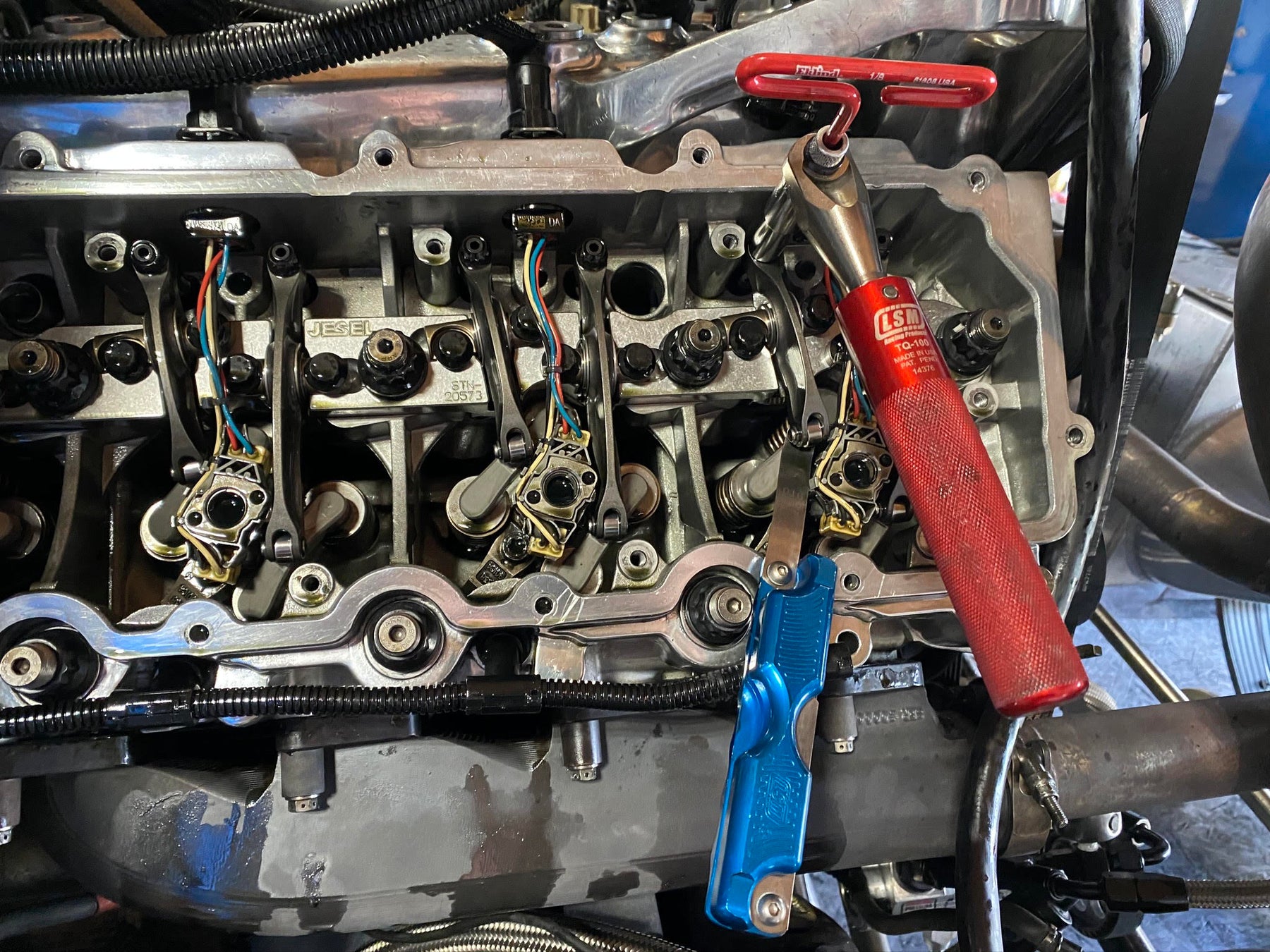

Reliability Under Extreme Conditions

In engines that see high RPM, big boost, or heavy loads (like drag racing, sled pulling, or serious street builds), solid roller cams paired with high-quality valvetrain components (like Jesel rockers) provide unmatched reliability. They’re designed to take the abuse without the compromise or variability of hydraulic systems.

The Bottom Line

If your goal is maximum performance, precision, and reliability—especially in engines that live at high RPM or see extreme conditions—a solid roller camshaft is the clear winner. It lets you take full advantage of aggressive cam profiles, offers early warning of valvetrain issues, and removes hydraulic variables that can hurt performance or lead to failure.

At Kill Devil Diesel, we design our camshaft and valvetrain packages to deliver these advantages, helping diesel owners and racers get the most out of their engines.