The one thing that's been missing from the 6.7 platform is a reliable fuel system...save $10-15k+ dollar fuel system repair bills resulting from the failed CP4. The DCR fuel pump conversion kit was developed in collaboration with S&S and Stanadyne/Pure Power and utilizes a robust pump design used in other original equipment markets around the world. The pump features S&S designed pump cam, metering units to make it a drop in ready solution for the faulty CP4. No tuning required.

FORD 6.7L POWER STROKE CP4 PROBLEM

The CP4 has a well-earned reputation for failing without warning, creating sudden power loss, and taking out the expensive high-pressure fuel system in the process. Despite having to deal with being broken down on the side of the road, truck owners will be facing fuel system repairs that can easily exceed $10,000. The unreliable reputation is supported by recalls and lawsuits leveled at various auto manufacturers that use the CP4 in their production vehicles.

DIRECT DROP-IN SOLUTION

Removing the CP4 is the obvious solution, yet developing a durable plug-and-play CP4 replacement with OE fit and function is the game-changing catalyst created by S&S Diesel Motorsport and PurePower. Starting off with a proven Stanadyne DCR fuel pump design, a joint team of S&S and PurePower engineers developed a variant specifically for the Ford 6.7L Power Stroke that matches the CP4 output curve and does not require any calibration changes. Combining that with OE-grade braided hose and steel fuel lines gives Ford Super Duty owners a more-reliable CP4 replacement that looks and performs like original equipment.

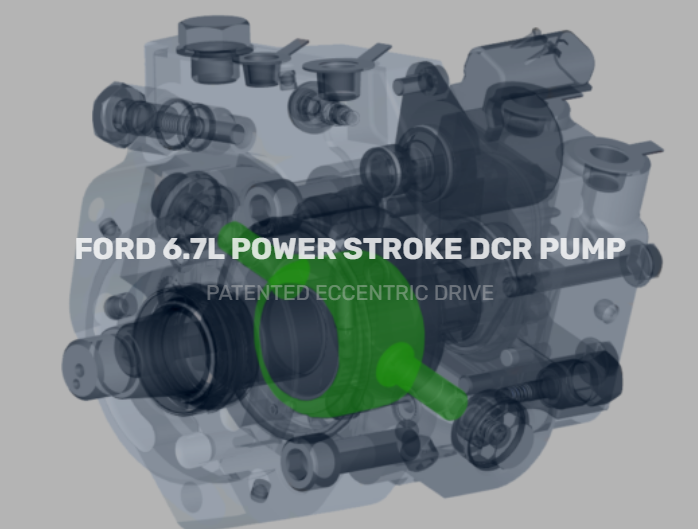

DURABLE DCR HIGH-PRESSURE FUEL PUMP

The two-piston DCR pump is based on a compact and modular design for easy integration, has low hydraulic and acoustical noise, features ultra-fast response times, and is biofuel and low-lubricity fuel compatible. It uses a patented eccentric drive pumping technology, with pressure-lubricated cam and bushings, for increased performance, efficiency, and benchmark durability. The Fuel Control Actuator (FCA) uses high-quality corrosion-resistant components and proprietary features to prevent large debris from entering the actuator, providing exceptional robustness for longevity and durability in harsh environmental conditions. The DCR can provide a max fuel delivery of 1,250 mm3 per revolution (25% more than a CP4.2), producing plenty of flow for worn injectors that have high return.